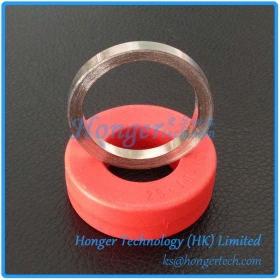

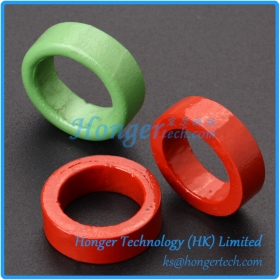

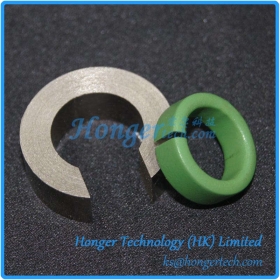

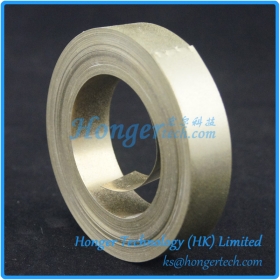

Besides Mu Metal shielding parts used in low frequency magnetic field, Honger also manufactures and supplies Mu Metal ring cores for high accuracy current measurement applications.

Typical applications of these cores are in power transmission systems, rail networks, and in conjunction with phase balancing software in sensitive 3 phase installations, to achieve maximum machine efficiencies.

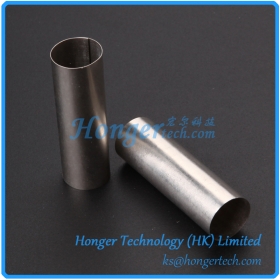

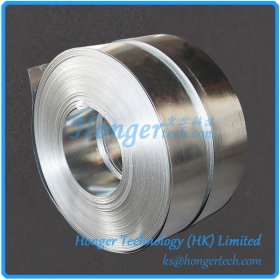

We are able to produce Mu Metal ring cores from 20mm diameter up to 1000mm diameter, and these can be produced from Mu Metal strip in thickness of 0.1mm to 0.2mm. Our factory is fully equipped with coil slitters, winding machines, and hydrogen furnaces, enabling us to provide rapid delivery on all cores, from singular items to batch runs.

Packaging & Shipping

1. Carton boxes package for small quantity

2. Wooden Case for Large Quantity (Make sure the products shipped in safety)

Our Services

1. Before purchase

Any comments or advice from you are highly welcome. We will try to answer all your call and reply your every requirement.

2. Sample provided

Samples are normally offered. Sample will be charged according to the quantity or the value of the material. We can return this charge in the following order payment. So don't worry about the quality, you have every chance to try and inspect before you place the order.

3. After-sale service

We will follow every order from beginning to the end. Any quality problem happens, just send us a message or email. We will process it as soon as possible. We will replace the material if they are inspected defective.

We believe in quality, there's no best, only better! If you are the one who pursue the same, please don't hesitate to contact us now!

Tel : 13312903299 / 0517-88288066

Tel : 13312903299 / 0517-88288066 Email : ks@hongertech.com

Email : ks@hongertech.com